Vital Factors To Consider for Guaranteeing Top Quality and Long Life in operation Engines

When taking into consideration the acquisition of a made use of engine, ensuring its top quality and durability requires a diverse approach. Upkeep history is a pivotal aspect, as it offers understanding right into the engine's previous treatment and prospective future integrity. Past documents, a thorough inspection of physical elements-- such as belts, tubes, and seals-- can reveal concealed concerns. Efficiency testing is likewise essential, supplying a picture of the engine's functional effectiveness. However, understanding the subtleties of these assessments and their implications can be complicated. What are the crucial methods that can be utilized to browse this complex examination procedure successfully?

Engine History Analysis

In the world of utilized engines, a complete engine history analysis is paramount to making certain top quality and reliability. Comprehending an engine's past can supply critical insights right into its performance abilities and potential future durability. A precise background evaluation includes several key facets that play a substantial duty in analyzing an engine's condition. Maintenance documents are indispensable. Normal maintenance, including oil modifications, filter replacements, and set up tune-ups, suggest that the engine has actually been well-cared-for, minimizing the chance of unpredicted failures.

Engines that have undertaken considerable repair work might have underlying problems that might resurface. Examining the engine's mileage can serve as an indicator of wear and tear. An engine utilized largely for long-distance freeway driving might be in much better problem than one subjected to regular stop-and-go city website traffic.

Essentially, an exhaustive examination right into an engine's history is essential for making educated buying decisions. used engines for sale.

Comprehensive Inspection Guide

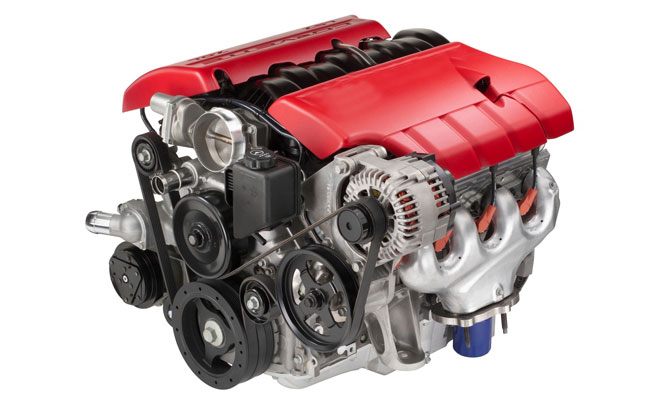

While comprehending an engine's background supplies beneficial context, a comprehensive examination is the following step to ensure its present condition lines up with historic data. The examination needs to begin with a visual analysis, looking for signs of leaks, corrosion, and uncommon wear. Evaluate the exterior for oil spots or coolant marks, which might show underlying issues.

Next, review the engine's installing system for any loose screws or irregularities that might affect efficiency. Pay close attention to the condition of belts and hose pipes, as these elements are essential for optimum engine functionality. Check out for fractures, fraying, or any type of signs of damage.

Identifying Use and Tear

Identifying signs of wear and tear is vital for examining an utilized engine's durability and integrity. It entails a careful evaluation of different engine components to determine their existing state and prospective future efficiency. Typical indicators consist of noticeable deterioration, which can affect metal components and jeopardize architectural integrity. Rust on or around the engine block, cylinder heads, and exhaust manifolds is especially concerning.

Another crucial facet is evaluating the engine's seals and gaskets. These components are important for maintaining proper pressure and avoiding fluid leaks. Evidence of oil leaks or used gaskets often suggests degeneration, possibly bring about extra extreme concerns otherwise attended to immediately. In addition, irregular noises during engine operation, such as knocking or ticking audios, might suggest interior damage or excessive wear on relocating components like pistons or bearings.

The condition of belts and Continued hoses is Discover More Here similarly vital, as they play an important role in the engine's total function. Fractured or frayed belts and brittle pipes are indications old that can result in engine failing if ignored. Last but not least, checking out the oil problem and filter can offer understandings right into previous upkeep practices, as unclean oil or clogged filters recommend neglect and sped up wear.

Performance Testing Fundamentals

Evaluating the wear and tear of engine elements sets the phase for a thorough assessment through performance screening. Efficiency testing serves as a vital measure in determining the functional stability of an utilized engine.

Utilizing dynamometers is an usual approach in performance testing. These devices measure the engine's output throughout numerous problems, providing an in-depth profile of its functionality. Furthermore, on-road screening enhances dynamometer assessments by observing engine behavior under common driving situations, ensuring it satisfies the needed criteria for both safety and security and performance.

These tools analyze engine management systems, recognizing mistakes in electronic components that could influence efficiency. Comprehensive testing not only validates the engine's functional status but additionally help in forecasting future upkeep demands.

Maintenance and Care Tips

Correct maintenance and treatment are critical to extending the life expectancy of a used engine and guaranteeing its constant performance. Normal oil modifications are critical; making use of the maker's advised oil type and quality can avoid too much deterioration. Additionally, oil filters need to be changed concurrently to maintain optimal lubrication and cleanliness within the engine.

Checking liquid degrees, including coolant, transmission liquid, and brake liquid, is crucial. Making sure these fluids go to proper degrees aids avoid overheating and various other mechanical concerns. Evaluating belts and hose pipes for indicators of wear, such as cracks or fraying, can avoid possible failures that might result in expensive repairs.

Routine evaluation of the air filter is also needed, as a clean filter guarantees effective air movement and combustion, therefore optimizing engine efficiency. Ignition system must be examined and replaced when needed to keep efficient fuel burning and prevent engine misfires.

Lastly, routine analysis checks making use of specialist tools can identify prospective problems prior to they come to be substantial problems. By adhering to these maintenance and care ideas, utilized engine proprietors can guarantee their engines continue to be dependable, effective, and capable of doing well over an extensive duration.

Final Thought